6 Strategies to Tame Supply Chain Turbulence and Build Resilience

Supply chain and component sourcing challenges continue to impact businesses large and small. Lasting effects from pandemic-related shutdowns, inflation, ongoing war in Ukraine and other circumstances have exposed vulnerabilities — and disrupted global production and logistics.

According to consulting firm McKinsey & Company, 81% of companies have adopted more complex supply chain management strategies to mitigate the effects of the disruption. Companies that can’t meet the demand will confront customer service challenges and the likelihood of lost business and missed opportunities. Meanwhile, nimble businesses with stable vendor relationships and domestic supply chains in place are likely better equipped to pluck away customers.

Dialing Down Disruption

While there’s no one-size-fits-all solution for solving supply chain problems, businesses can take steps to mitigate issues.

- Conduct scenario planning. Today’s complex and interwoven supply chains raise the odds that an unexpected event will ripple across companies and inflict pain. Almost no one foresaw a pandemic that would essentially shut down the world, for example. But by mapping out these what-if scenarios ahead of time — instead of having to react in the moment — companies can make a plan to protect themselves against risk and disruption. McKinsey & Company found that only 37% of companies have implemented scenario planning. Yet, those that did so were two times more likely than peers to report no problems in 2022.

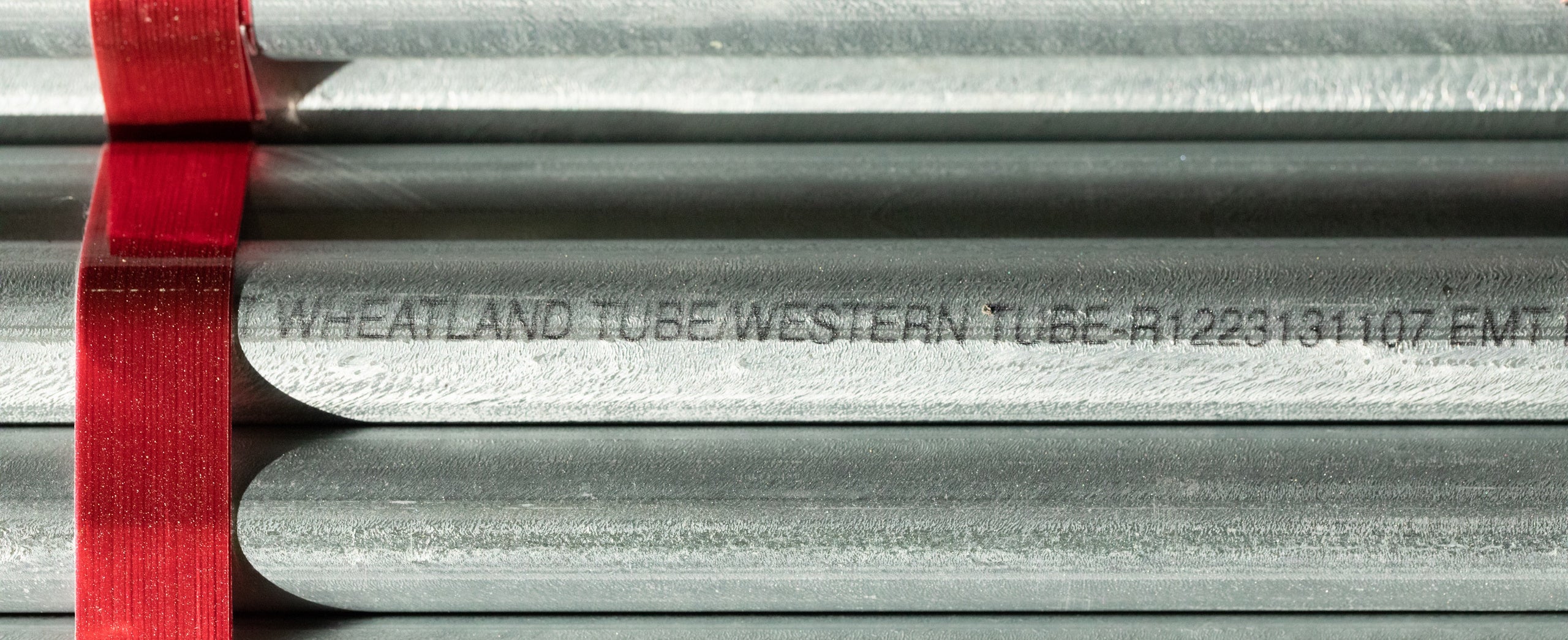

- Buy domestic. Many supply chain problems involve global shipments that are more prone to disruptions, delivery delays, traceability challenges, mountains of paperwork and sometimes additional fees and taxes. “When you’re buying foreign [product], you’re not quite sure what you’re getting all the time … and you don’t always have the governing bodies that are paying attention and the eyes watching it,” explains Gene Metro, quality assurance manager at Zekelman Industries (ZI). Adopting a strategy that prioritizes domestic sourcing can reduce complexity, improve processes and speed fulfillment. In fact, 40% of companies say they are now developing regionalized supply networks to increase supply chain resilience, nearly doubling from 25% in 2021, according to the McKinsey & Company survey.

- Choose proven and reliable suppliers. Due diligence is your friend. It’s vital to check references, review financials and scrutinize a business partner’s technology framework, commitments to reinvesting capital, and focus on customer service and quality. For instance, one of the ways Zekelman maintains the high quality of its domestic pipe products is by using robust product tracking, Metro explains. “We have the traceability all the way from the steel coil we purchase from domestic mills to the individual piece of pipe installed at a job site.”

- Ensure that your enterprise resource planning (ERP) system — and your partner’s — is up to date. A supply chain is only as good as its weakest link, and even the most tech-savvy business must depend on others in its supply chain for data. As Shawn Londrie, director of production planning at Zekelman explains, “Real-time information is critical to what we can do. So we have very good visibility across our entire supply chain — and when we’re going to get material produced and out the door [to the customer].” Such forecasting can also help trim costs and speed deliveries to customers.

- Harness predictive analytics and AI. Although modern ERP systems deliver broad and deep insights into a supply chain, many enterprise organizations are also turning to predictive analytics, machine learning and digital twins, which are virtual models that can be used to run simulations. These tools help a business act on information, so you can make any necessary alterations or improvements in more agile and flexible ways.

- Communicate often. As businesses run lean, the importance of keeping different stakeholders updated is more critical than ever. Events and business conditions change rapidly, so it’s important that suppliers and others in the supply chain are all working with the same set of data and information.

Getting Smart

While supply chain disruptions can introduce formidable challenges, they also provide opportunities to gain a competitive advantage. Without a resilient supply chain, many product deliveries and construction projects can slow to a crawl, and cost overruns can multiply — and divide companies. Organizations that are ready with a clear and functional strategy to mitigate those disruptions can not only survive but also thrive by building resilience amid uncertainty.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields