Storing Steel Pipe? Use these 3 Strategies to Stop Corrosion in Its Tracks

Steel is strong, durable, and versatile. But the widely used metal also has an Achilles heel: its susceptibility to corrosion.

Despite its strength, steel can start breaking down quickly when exposed to elements like water and sunlight. Companies must be knowledgeable of this when storing or using steel pipe products outdoors, or the results can be catastrophic.

One cautionary tale is the back-to-back oil spills from BP’s Prudhoe Bay pipeline in Alaska. The largest of the spills, in March 2006, allowed more than 200,000 gallons of thick crude oil to escape from a section of badly corroded pipe. The result was the largest and most devastating spill on Alaska’s North Slope to date. BP was forced to pay $45 million in fines and spend over $200 million to replace transit lines where the leaks occurred.

So how can companies stay vigilant against pipe corrosion? Here are some simple strategies to stop rust before it starts.

- Dry Storage

When storing steel, remember this simple tip: Dry is good. Wet is bad. The drier the surrounding environment, the less likely it is for steel to corrode and rust.

Ensure your storage area is dry, with minimal opportunity for steel to come in contact with water, condensation, or humidity. Avoid storing pipe on the floor or storing it with other materials if there’s a chance it could increase moisture.

- Galvanizing

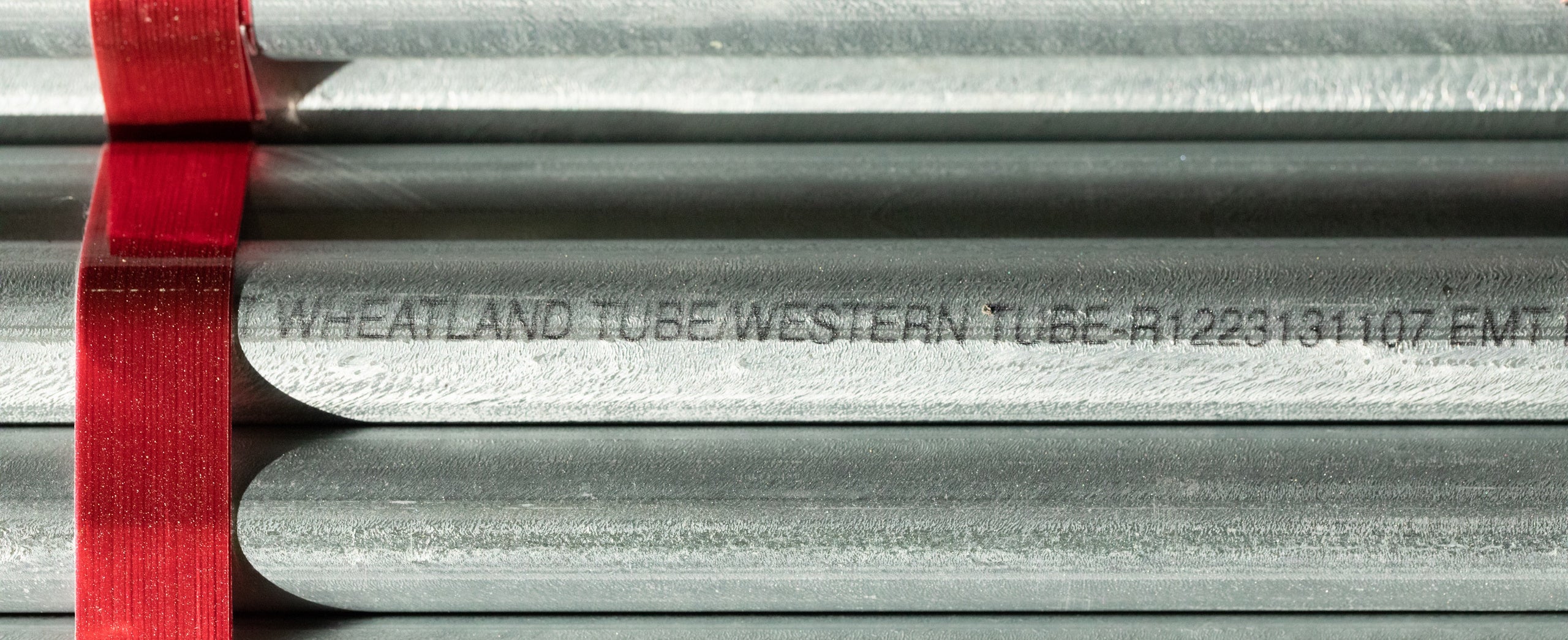

Galvanization is when pipe manufacturers apply a zinc coating to the pipe at the end of production. At Zekelman’s Wheatland Tube, our hot-dipped galvanizing process submerges pipe in a pickle tub to remove all scale and rust. The pipe is then rinsed and dunked in a pre-flux to ensure the zinc adheres properly — inside and out — before the bare pipe is dipped into a kettle of molten zinc.

With galvanized pipe, the zinc coating acts as a protective barrier to make steel more durable and prevent corrosive substances from reaching the steel.

- Coated Steel

While this might seem contradictory to our first strategy, lathering steel in oil creates a protective barrier against rust. With an oil coating, moisture can’t react with the steel’s composition to produce rust.

But oiling isn’t a perfect solution, making the steel very slippery and dangerous to move or handle. Plus, oil must be constantly reapplied to keep the protective layer active, which takes time and energy.

After heavily researching several different coating methods for piping, product developers at Wheatland created an ultraviolet light-cured, no volatile organic compounds (no-VOC) paint coating to provide superior corrosion resistance, even after prolonged sun and water exposure. “The pipe can be stenciled, handled, and packaged without damage,” says Greg Maurer, Technical Services and Quality Assurance Director at Wheatland.

The company had previously tested a water-based coating that would take days to fully dry. “It would go outside and get rained on, and you would get nesting lines and all kinds of rust,” explains Kevin Kelly, President of Standard Pipe at Wheatland.

Zekelman’s Ultra Z-CoatTM is applied to the outside of the pipe and then cured in a UV light chamber, where it dries instantly, so it’s ready to handle right away. The coating is formulated to be environmentally safe. “It’s a 100% solids coating, meaning that there’s no water, no co-solvents, no VOCs, so none of that is going into the environment,” says Maurer.

Proactive Prevention

Steel pipe is the backbone of many U.S. products and structures, but it’s only as strong as its corrosion resistance. Proactive maintenance is key, whether it’s keeping pipe dry, investing in galvanized steel, choosing protective coatings, and/or regularly inspecting stored material.

An ounce of prevention against rust truly pays off in the long run by maximizing the lifespan of your steel pipe.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields