Restoring American Manufacturing in 2025

Making products in America improves quality, creates jobs, and uplifts communities for generations.

The manufacturing landscape in the United States was significantly eroded during the past 40 years. Now, it’s time to bring it back.

Due to new developments in international trade relations, a renewed focus on domestic manufacturing has reached the United States. Companies across a wide range of industries recognize the necessity of balanced trade and reduced dependence on global supply chains to ensure the availability of vital products for American businesses and consumers.

As a result, American manufacturing is poised to experience a significant resurgence. This is particularly important for industries impacted by unfairly traded materials and products. From computers and smartphones to basic minerals and steel products, making more of these items in America is smart, sustainable, and cost-effective. America is ready to build things at home again, and we applaud the current administration’s actions to make it happen.

Let’s explore why investing in domestic manufacturing leads to better outcomes for American workers, companies, and communities.

American Manufacturing is Resilient to Disruption

Increased costs associated with importing raw materials and consumer products, as well as supply chain failures and delays, have become a standard feature of the global trade landscape in the 2020’s. For businesses relying on reliable access to raw materials and manufactured components, ever-changing political currents and supply chain disruptions add complexity and cost to production and procurement.

Manufacturing more goods in America eliminates these challenges. By producing domestically, companies can avoid business disruptions due to political showdowns or supply chain difficulties. Businesses depending on building materials, for instance, can enjoy stable, predictable pricing and inventory when they source domestically for the entirety of a project.

Many direct-to-consumer companies are already leading this shift. For example, Apple’s pledge to invest over $500 billion in U.S. manufacturing will include high-skilled job and education initiatives in nine different states, ensuring a secure domestic supply chain of advanced technology like silicon chips and AI-based cloud computing servers. These developments guarantee product availability while bypassing the volatility of global markets.

Companies relying on resilient domestic supply chains benefit from reduced business disruption and shorter production lead times. As a result, businesses should view American manufacturing as a profitability maximizer and a safeguard against volatile market conditions. By eliminating costs associated with international production, logistical delays, and trade disagreements, businesses can reduce vulnerabilities while cutting long-term costs.

American Manufacturers Make Superior Products

Alongside an increase in dependable supply, companies that invest in reshoring the manufacturing of crucial goods should expect product quality to increase as well. While outsourcing offers initial cost savings, inconsistency in product quality from overseas producers often leads to costly change orders, significant timeline delays, and the inability to deliver on promises to customers. American manufacturers, however, excel at controlling each phase of production to deliver superior goods built for longevity and high performance. By bringing manufacturing back to the United States, companies can ensure that their products meet or exceed quality standards and satisfy customer expectations.

Over time, the production of advanced items has become increasingly reliant on overseas infrastructure, particularly in Asia. However, the tide is changing as technology hardware companies begin to recognize the need for American precision in their production. For example, Intel’s $32 billion investment in new Arizona-based facilities will create 10,000 high-skill jobs alongside reliable, high-grade American semiconductors. Similarly, Nvidia recently announced plans to manufacture up to $500 billion worth of AI chips and supercomputers entirely in the United States by 2029. Other global powerhouses like GE Aerospace, Toyota, Johnson & Johnson, Ford, Eli Lilly, First Solar, and Merck are following suit. By keeping production local, technology companies can ensure that their innovative offerings maintain a level of reliability that overseas production infrastructure cannot consistently achieve. As a result, American production benefits end consumers and insulates the economy from international trade disputes like the one that has defined the first half of 2025.

American manufacturers also distinguish themselves further by continuing to innovate their products and manufacturing methods. Advanced safety technology, cutting-edge automation, and sophisticated research and development continually energize American manufacturing to deliver consistent excellence and reliability. When a company makes their product in America, they can count on a level of quality and consistency rarely found elsewhere.

American Manufacturing Supports Communities

Money spent on American-made goods contributes to more than durable supply chains and high-quality products; it also uplifts American communities. By reshoring manufacturing in the United States, the economy sees increased activity that contributes to robust public services and community programs. In addition, domestically manufactured products sustain millions of jobs and empower future generations of workers through vocational education and training.

When it comes to community building, manufacturing plays a pivotal role. The impact of manufacturing extends far beyond the factory floor due to the multiplier effect. For every job directly created in manufacturing, an estimated 4.8 additional jobs are generated in other sectors to support the manufacturing ecosystem. These jobs take the form of truck drivers ensuring timely delivery, cleaning crews maintaining facilities, maintenance technicians keeping operations running smoothly, and restaurants serving families. This ripple effect makes manufacturing an economic utility and a promising vehicle for rapid growth and prosperity wherever a manufacturing facility opens.

With a wide range of reshoring efforts supporting domestic skilled labor, other companies are finding it easier to follow suit. Recently, Siemens doubled down on its U.S. based initiatives by investing over $10 billion to create more than 900 skilled manufacturing jobs in Texas and California. This investment aligns directly with building stronger supply chains for high-tech industries and construction, further demonstrating the multiplier effect of domestic manufacturing investments.

For future workers, a return to American manufacturing also fosters job opportunities for the next generation of engineers, operators, and production specialists. Using locally sourced, American-made products is a powerful way to foster economic growth, support sustainability, and build stronger communities for future generations.

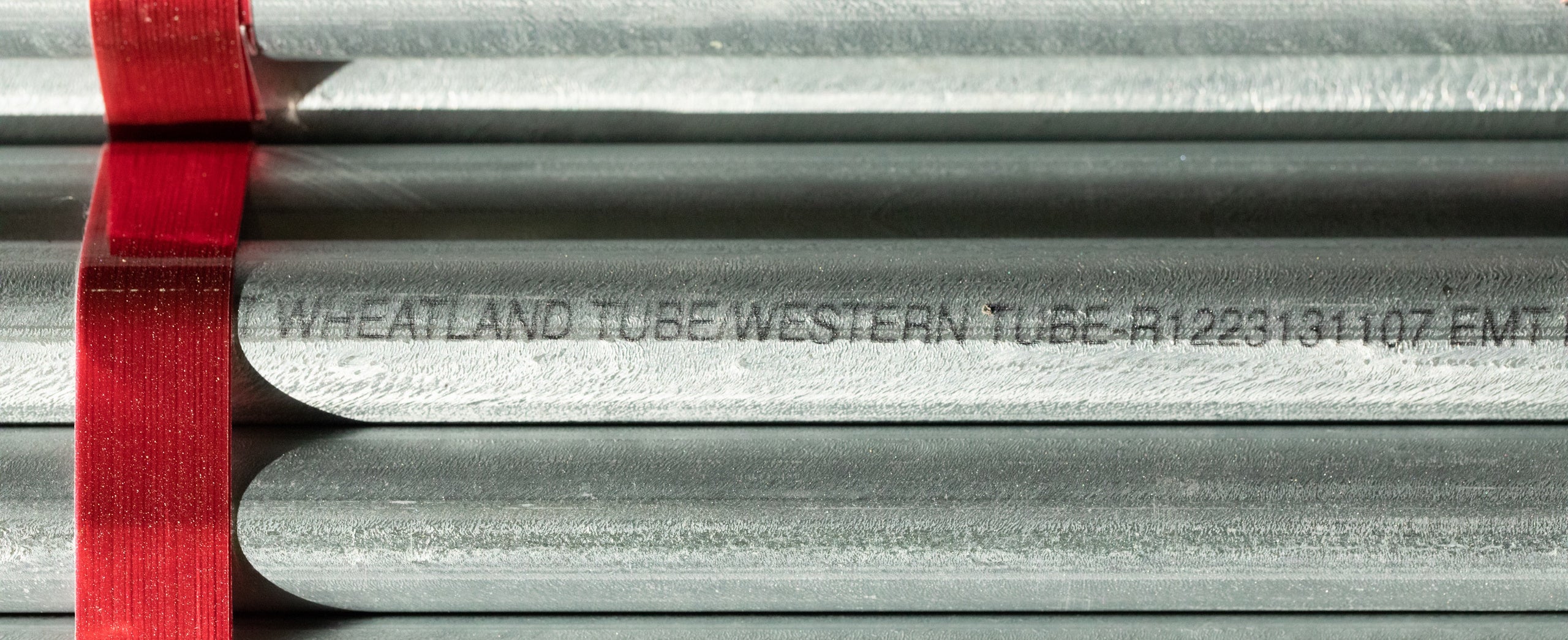

How Zekelman Does its Part

At Zekelman, we proudly support the resurgence of American excellence, innovation, and quality by continuing to manufacture 100% of our products domestically. From investing in cutting-edge warehousing technology that ensures swift inventory procurement to our rigorous production standards, we fuse the American spirit of quality and efficiency into everything we do. Through our Demand Domestic initiative, we amplify this impact by encouraging distributors and contractors to choose American-made materials. This creates jobs, strengthens local economies, and upholds our nation’s legacy of manufacturing durable products. As more builders opt for American materials, an increasing number of steel products can be found hiding in plain sight. From electrical conduit in apartment buildings and parking garages to HSS columns in massive stadiums and concert venues, our products power and support a stronger America.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields